Building a dashboard to control stock levels.

Project background

There was a need to create the dashboard I scoped on this project that could support data-driven decisions, to report on the stock levels for different products.

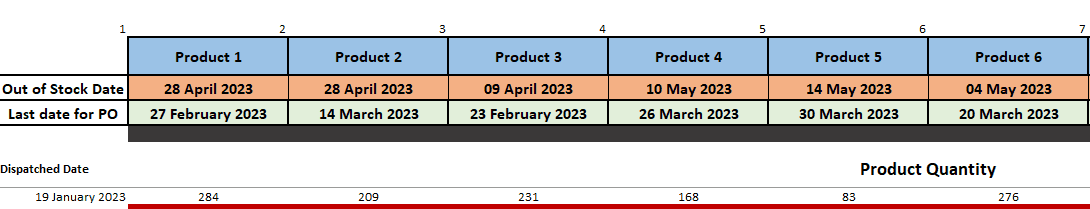

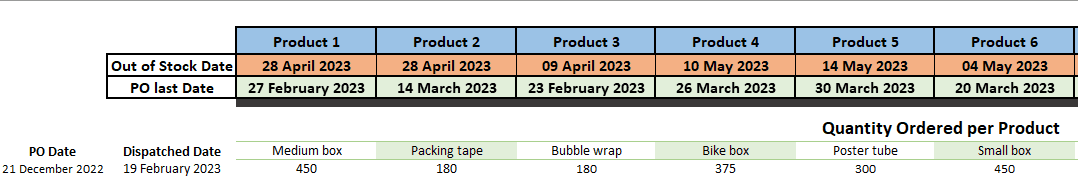

I have also added to the dashboard a section to prescribe when a Purchase Order (PO) should be made by in order to keep a safe stock level.

I've created it joining several tables from our data base (SQL Server Management Studio), and using Power Query to clean it and prepared.

This project has helped to tackle three main issues:

No stock available. Customers are still able to place their orders, but this situation generates extra work for Customer Services, and ultimately a loss in revenue if the customers decide to cancel their orders.

Traceability. Reducing stock discrepancies, when the actual stock have on hand does not match what's recorded in our system, and making warehouses accountable for.

Operational Costs. Companies usually order more stock than needed due to the lack of an inventory management system. More products are stored for a longer period of time and in larger volumes, generating a higher cost. Also, the transport cost will soar to maintain customer satisfaction, as usually 2 deliveries will have to be made for the same order.

How?

Using my Project Management and Stakeholder Management skills, and applying the Data Analytics life cycle.

Understanding the stakeholders requirements and managing expectations.

Project scoping.

Mining, cleaning and preparing the relevant data.

Analysing, modelling and implementing iteration.

Final results

The financial impact of this project during a whole year was estimated as:

+£7k, gain in revenue, reducing the orders cancelled due to a stock issue.

+£350, increasing traceability, reducing the stock discrepancies and the cost for the goods lost.

+£5.2 k reduction on operational cost, decreasing storage and transport cost.